Commitment to Quality

At Star Industries, quality is the cornerstone of our operations and a key driver of our long-term success. As an ISO 9001:2015 certified organization, we adhere to a well-defined Quality Management System that governs every stage of our manufacturing process—from raw material selection and process control to final inspection and delivery. Through continuous monitoring, documented procedures, and a culture of continual improvement, we ensure consistent product performance, operational reliability, and complete customer satisfaction.

Robust Quality Control System

Our quality assurance process covers every stage of manufacturing—from incoming raw material inspection to in-process monitoring and final product verification. Each component is produced in strict accordance with approved drawings, specifications, and customer requirements.

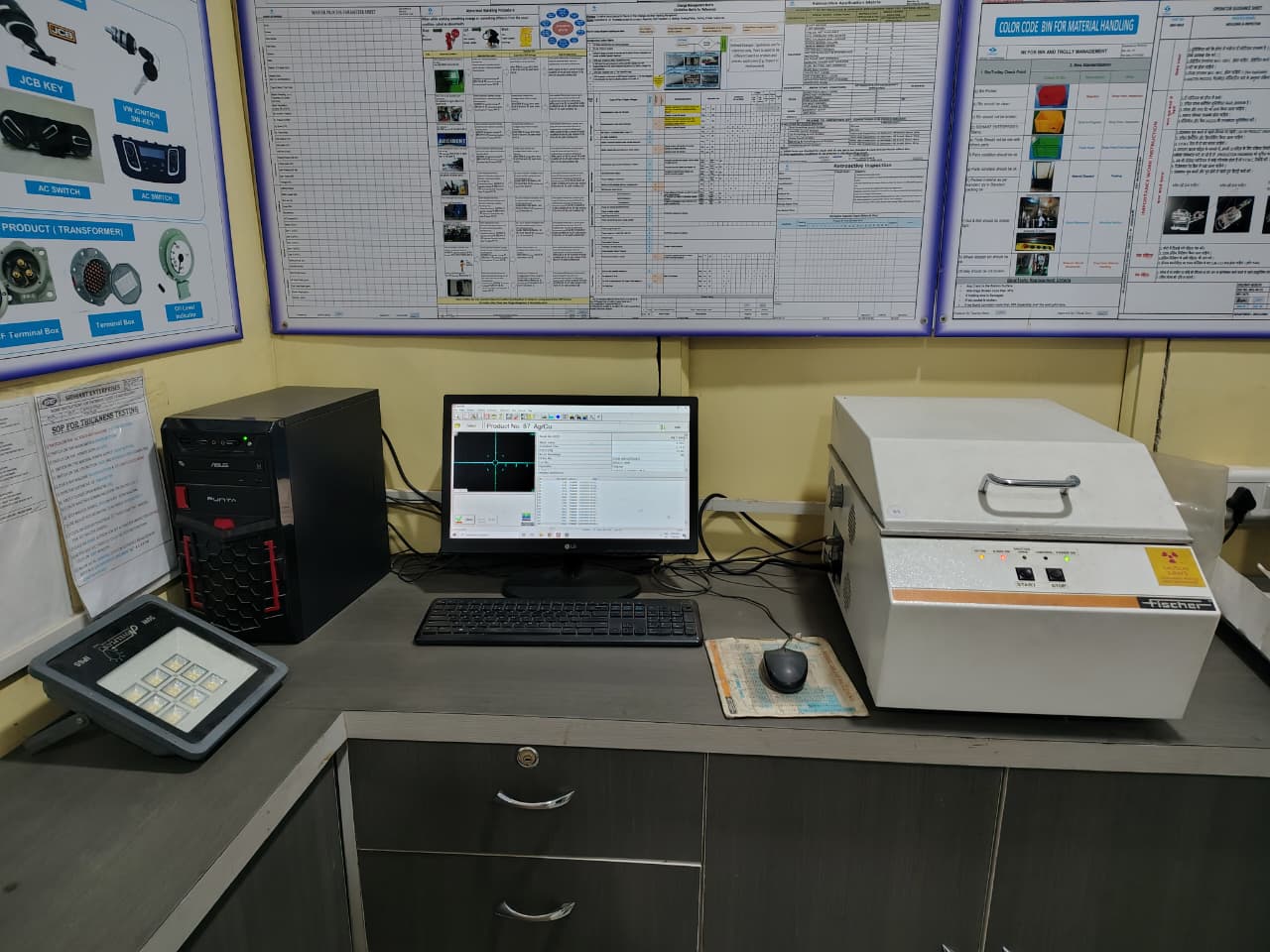

Advanced Inspection Facilities

We utilize modern inspection and measurement equipment to ensure high accuracy and tight tolerance control, including:

In-Process & Final Inspection

Skilled Quality Team

Our experienced quality engineers and inspectors follow standardized inspection plans, control charts, and corrective action systems to continuously improve processes and product quality.

Continuous Improvement & Compliance

We actively practice continual improvement through root cause analysis, corrective and preventive actions (CAPA), and regular internal audits. By closely monitoring process performance and customer feedback, we ensure compliance with quality standards while consistently enhancing product quality and operational efficiency.

Customer-Focused Quality Assurance

We ensure complete traceability, transparent inspection records, and timely corrective actions, reinforcing our commitment to delivering products that meet and exceed customer expectations.